Having advanced production equipment and exquisite craftsmanship. From raw material processing to finished product assembly, each link is efficiently connected to accurately meet the diverse needs of different customers. Whether it is standard models or customized products, they demonstrate excellent production capabilities with high quality and short delivery time.

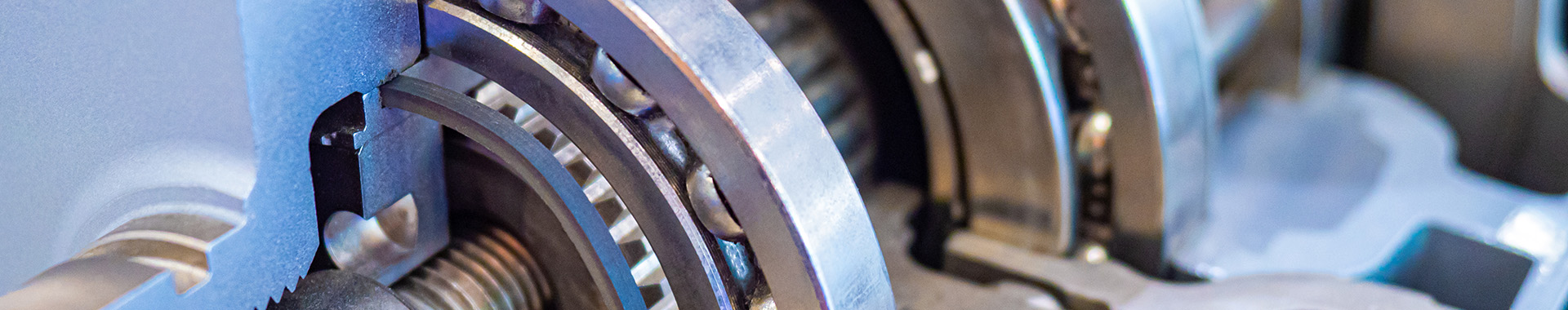

A strict quality inspection system has been established, and a comprehensive quality management system has been established. Starting from raw material procurement, every bearing seat must undergo strict quality inspection processes, including non-destructive testing, dimensional accuracy testing, and performance testing. The product qualification rate is far higher than the industry average.

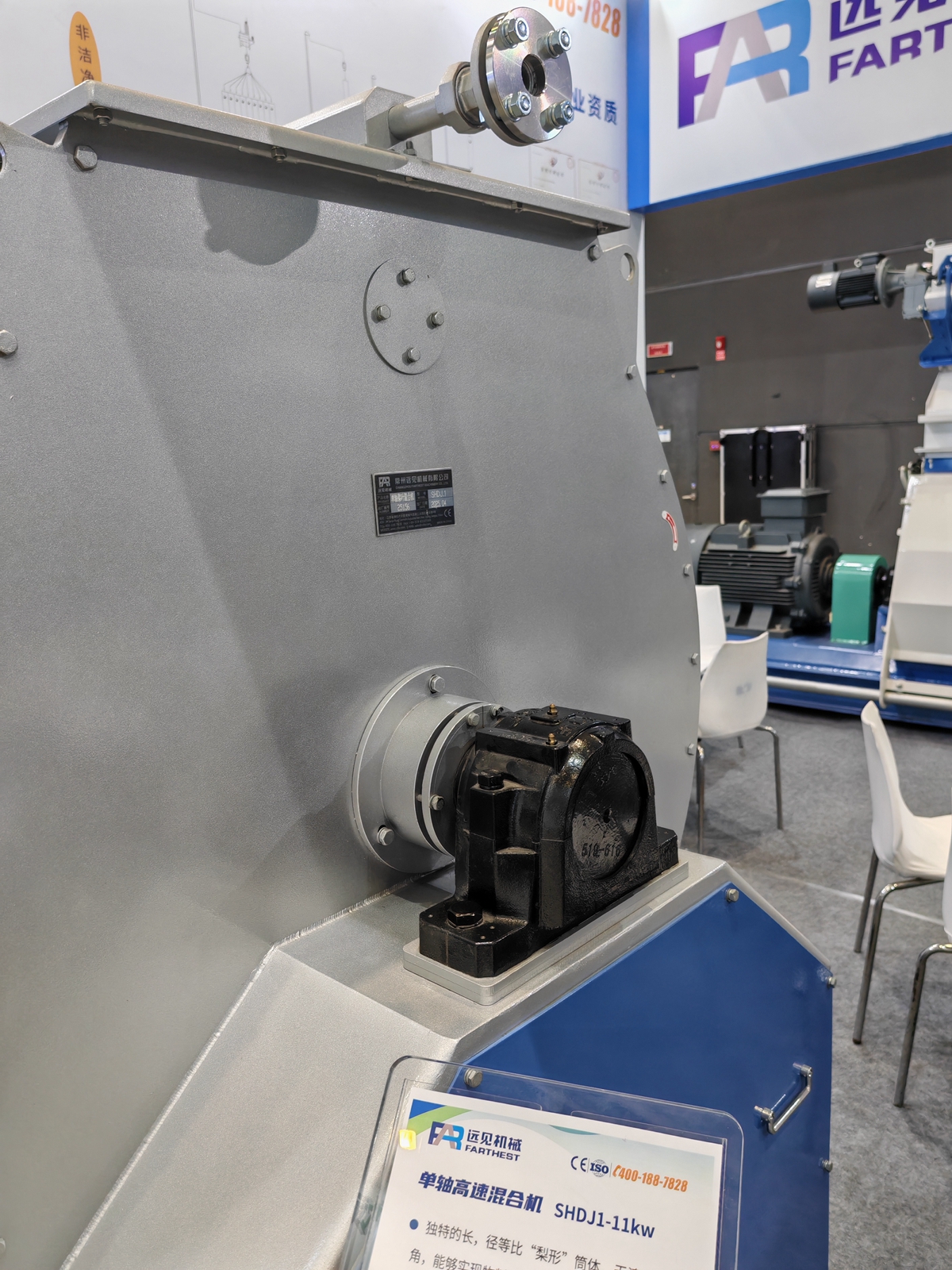

We provide comprehensive customized services and can design and produce bearing seats that meet customers' special needs, such as non-standard sizes, special material requirements, or specific installation environments, in a short period of time. From conceptual design to finished product delivery, we work closely with our clients to ensure that every customized product is perfectly adapted to their equipment.